What made you select MRC Component’s SoftProtector® Cores to feature? How does the product family differentiate from others/what value does it offer?

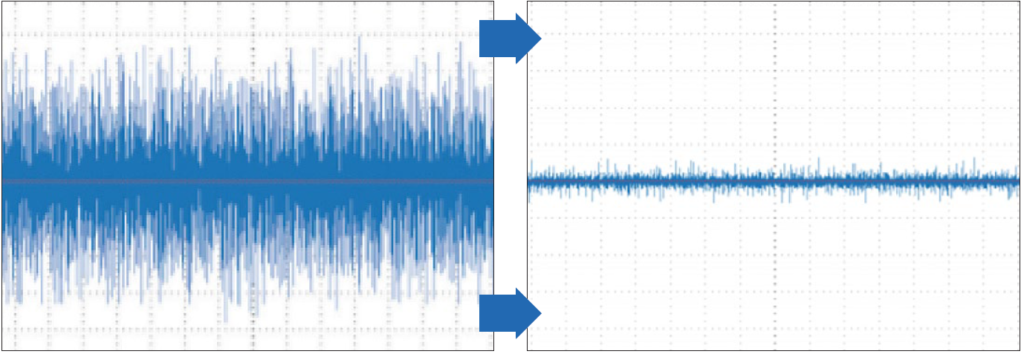

MRC Components SoftProtector® Cores are highly effective at mitigating harmful interference currents caused by modern high-power frequency converter operated systems, especially those operating at very high switching frequencies. Integrating an easy-to-retrofit SoftProtector Core solution minimizes instances of unexpected system failures and communication issues while ensuring that motor bearings, sensors, and motor terminals are protected. SoftProtector Cores enable system operation with a calculable maintenance cycle as they absorb and convert damaging high-frequency interface current into thermal energy that can be released from the core’s surface.

What are the key features and specifications of MRC Components SoftProtector Cores?

SoftProtector® Cores are advanced components that offer a broad range of key features:

- Interference reduction

- Motor bearing protection

- System reliability

- Extended motor terminal life

- Thermal energy conversion

- Single turn common mode choke

- Hybrid bearing switch potential

What are common markets/applications of SoftProtector Cores?

MRC Components Soft Protector® Cores cater to applications in the following areas:

- HVAC manufacturing

- VFD manufacturing (variable frequency converter/inverter)

- Paper-machine manufacturing or any VFD-driven installation

- Electric vehicle (EV) and automotive

- Pumps and large fans

- Renewable energies like wind-power, solar converter, and more

Author

-

Diana Artero is the Sales & Marketing Manager of MRC Components, an RFMW company. She has nearly 25 years of industry experience in soft magnetic cores and assemblies and has worked in both France and Germany during her career.