Inside the Brain of Modern Batteries: The Role of the Battery Management System

With electrification impacting various sectors from transportation to energy and beyond, the demand for smarter, more robust power management has never been more prevalent. Driven by the rapid adoption of electric vehicles (EV), renewable energy storage systems, and portable high-power applications, the global battery management system (BMS) market is anticipated to surge from $11.42 billion in 2024 to $46.96 billion by 2032.

Next-generation chargers and BMS require designs that deliver longer run-times, enhanced efficiency, faster reactivity, and optimized safety standards. Designing charging systems with advanced BMS requires a holistic approach to system-level designs.

From accurate charging and discharging to thermal regulation, battery cell balancing, intelligent diagnostics, and environmental resilience, BMS must be optimized for durability and reliable operation as many systems need to withstand temperature extremes, vibration, and moisture exposure. Battery pack configurations, cell count, arrangement, and voltage architecture, also play a key role in achieving efficient and safe performance.

What is a Battery Management System?

A battery management system or BMS is an advanced control platform purpose-built to monitor battery voltage, current, temperature and other critical parameters to ensure operation within safe limits. Cell imbalances and improper charging and discharging can greatly impact battery life and performance. The BMS balances the charge across the individual cells, protecting against over-charge or over-discharge which is crucial for safe operation, optimal performance and battery life.

Li-Ion Battery Management Systems

The growing adoption rate of BMS across eMobility and energy sectors is closely tied to the widespread use of lithium-ion (Li-ion) battery chemistries. Various types of Li-ion batteries, including Lithium Ferro Phosphate (LFP or LiFePO4), are an optimal selection for high-power applications, as they offer high energy density, long life cycle, and fast charging capabilities. However, they are also sensitive to temperature and voltage fluctuations. Without a robust BMS, designs face challenges like thermal runaway, cell imbalance or premature degradation.

The integration of BMS with Li-ion batteries helps maintain both performance and safety. Its core functions include:

- Charging accuracy through state of charge (SoC) calculations.

- Preventive maintenance capabilities through state of health (SoH) monitoring, fault detection, and protection.

- Battery cell balancing to ensure cell charge is maintained within safe limits.

- Smart communication and control integration through protocols like CAN, UART, or SMBus.

Combining High Power Charging with a BMS

The BMS serves an important role in maintaining proper battery health and combining the BMS with battery charging provides additional merit. While a charger provides the main power to charge the battery, a BMS is important for safety and optimizing performance. A basic charger cannot handle the cell imbalance complexities associated with high power Li-Ion battery packs. The BMS acts as the “brain” and monitors the health of the battery pack while communicating with the charger. If the BMS detects issues like low cell voltage or high temperature, it can adjust the charging current or stop charging completely.

4 Key Industries Utilizing Advanced BMS

As the electrification of mobility, tools, and infrastructure accelerates, advanced battery systems are critical pieces of high-power applications. While BMS offer overall benefits, it brings its own set of advantages and trade-offs in various sectors.

eMobility

Range charging efficiency, and safety are primary considerations in the e-Mobility sector. Whether in EVs or energy storage systems that support EV infrastructure, a high-power BMS is essential to maximize battery life and performance. In eMobility applications, BMS must also reliably communicate with inverters, chargers, and vehicle control units.

Key Applications

- EV chargers

- Portable EV chargers & Solar EV Chargers

- DC fast-charging stations with integrated energy storage

Industrial Automation

Industrial environments demand reliable, ruggedized solutions that can withstand harsh conditions like shock, vibration, and temperature variation. Additionally, modern BMS need to enable fast-charging and safe operation of large-format packs used in mobile or robotic systems.

Key Applications

- Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) in logistics and warehousing

- Battery-powered forklifts and material handling vehicles

- Backup and peak shaving battery systems for factories and warehouses

Aerospace and Defense

In addition to ruggedness, aerospace and defense designs for unmanned aerial vehicles (UAVs,) and drones must factor in considerations like weight, thermal control, and safety. Integrated BMS must provide precise fuel gauging, thermal runaway prevention, and fail-safe shutdowns in the event of extreme conditions.

Key Applications

- Tactical drones and surveillance platforms

- UAVs

Agriculture

Electric outdoor power equipment requires BMS designs that can handle weather exposure, rugged terrain, and must accommodate long idle periods (seasonal storage) while ensuring optimal battery life and safe operation.

Key Applications

- Battery-powered riding lawnmowers

- Cordless chainsaws, and trimmers

- Electric utility vehicles (UTVs) for farm or property maintenance

How to Design a Next-Gen Battery Charger with Solutions Available from RFMW

RFMW’s broad portfolio of power management solutions provide developers with innovative and best-in-class solutions to design future-ready BMS and chargers. Applicable semiconductor products include efficient SiC MOSFETs and rectifiers, and state of the art intelligent BMS ICs. Passive products include power and safety capacitors, magnetic cores, common-mode chokes, inductors, and transformers. Our solutions support the stringent performance, thermal, and safety requirements of high-power battery charging systems.

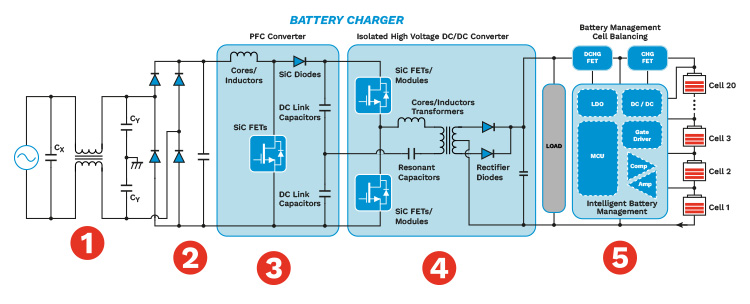

The following section highlights a common AC powered battery charger topology with integrated BMS. The function of each section is discussed as well as possible component options available from RFMW.

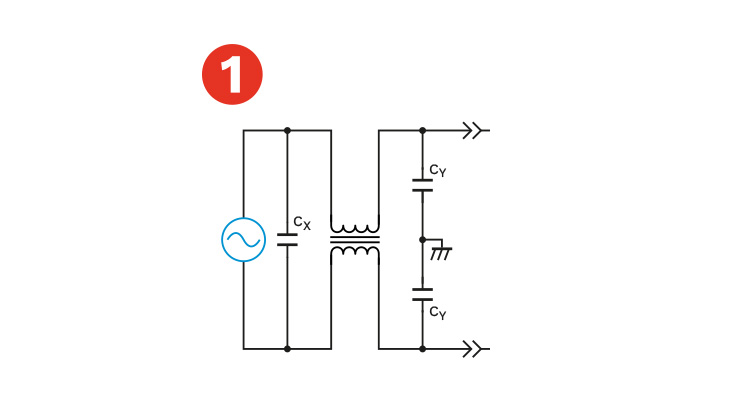

1. AC Input Filter Section

The AC input filter section is needed to reduce electromagnetic interference (EMI) and to prevent high-frequency voltage from passing through to the output. It is designed to filter out unwanted disturbances and protect circuitry from possible damage. It also prevents switching noise generated by the circuit from reaching the power line and interfering with other connected equipment.

AC input filters are designed to:

- Filter out high-frequency noise and electromagnetic interference (EMI) from incoming AC power.

- Protect downstream circuitry from voltage transients and conducted emissions.

- Minimize noise emissions to meet EMC compliance.

The AC input filter usually includes components like common-mode chokes, X and Y capacitors, inductors, and sometimes ferrite beads, arranged to attenuate both differential-mode and common-mode noise. It plays a critical role in maintaining stable BMS operation and safeguarding system performance in electrically noisy environments.

Featured Products

Capacitors

|

Knowles |

Frontier Electronics |

Magnetics

|

Frontier Electronics |

MRC Components |

|

Custom |

|

|

|

Custom |

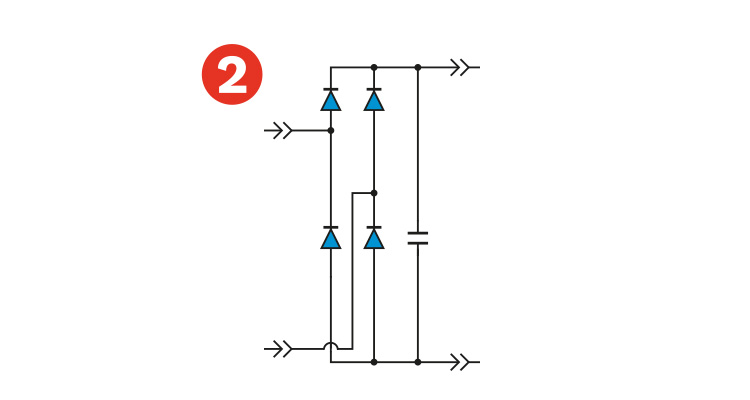

2. Rectifier Section

In a BMS that interfaces with AC power, such as in energy storage systems, UPS, and AC-DC chargers, the rectifier section converts the incoming AC voltage to DC by rectifying the AC and filtering with a capacitor to form DC for system use.

Key rectifier functions include:

- AC to DC conversion using diodes or actively-controlled rectifier circuits.

- Supplying DC power to downstream components like the PFC/boost and other DC requirements.

- Converting AC power to DC power which is essential for most electronic devices.

The rectifier section often follows the AC input filter and may include a bridge rectifier, smoothing capacitors, and sometimes power factor correction (PFC) circuitry to improve efficiency and reduce harmonics. Specific types of capacitors will vary based on voltage levels and ripple current capabilities. It’s essential for delivering clean, usable DC power within the BMS architecture.

Featured Products

Capacitors

|

Knowles |

|

Film: |

Rectifiers

|

Frontier Electronics |

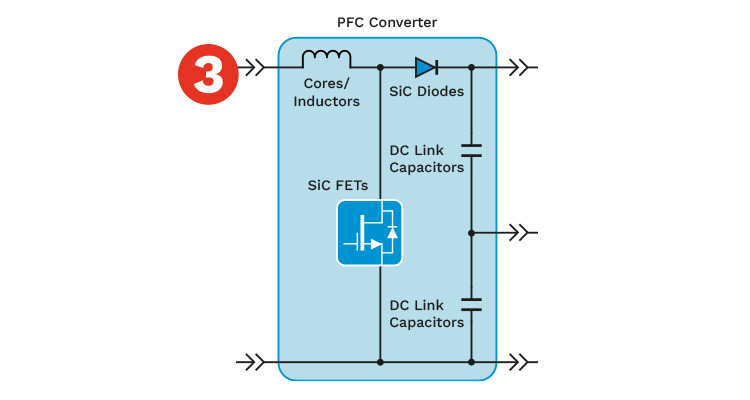

3. Power Factor Correction (PFC)/ Boost / DC link Section

The PFC/Boost section improves the efficiency and quality of power drawn from an AC source, especially in systems like energy storage or UPS applications. Power Factor Correction (PFC) shapes the current from the input AC source to be in phase with the voltage, to maximize the real power drawn from the input. The boost PFC topology is common due to the minimal part count, efficiency, and reduced complexity. The DC link capacitors act as an energy storage and smoothing component, stabilizing voltage fluctuations, reducing ripple, and providing a buffer for energy transfer between stages.

The PFC/Boost section’s main functions are:

- Correcting the power factor by aligning the input current with the input voltage, reducing reactive power and improving energy efficiency.

- Boosting the rectified DC voltage to a higher level suitable for downstream converters or battery charging circuits.

- Reducing harmonic distortion to meet regulatory standards.

The PFC/Boost ensures that the BMS draws power more cleanly and efficiently from the grid or AC generator and helps reduce losses, lower electricity costs, and meet EMC and power quality standards. The use of SiC MPS as the boost diode in continuous conduction mode is particularly effective in reducing switching losses and improving efficiency due to near zero reverse recovery and consistent performance over temperature compared to Si diodes.

Featured Products

Capacitors

|

Knowles |

|

Film: · DC Link |

Magnetics

|

Frontier Electronics |

MRC Components |

|

High Flux Core: |

|

|

Custom |

Custom |

SiC MPS Diodes and MOSFETs

|

CoolCAD |

Frontier Electronics |

|

|

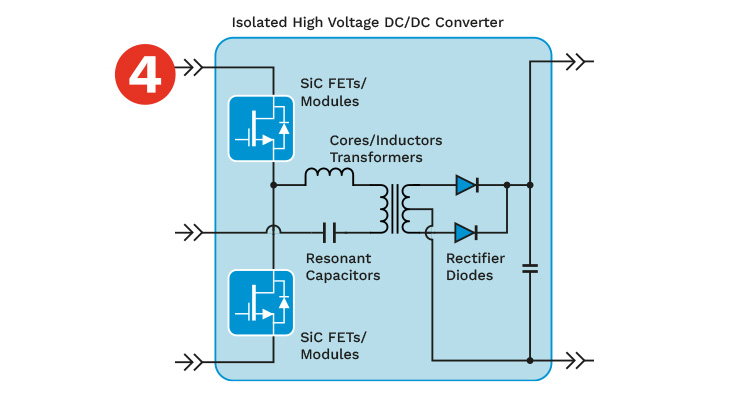

4. Isolated DC/DC Section

The Isolated DC/DC section provides galvanic isolation between the input and output circuits using a transformer. The magnetic coupling separates the input and output grounds and provides additional safety and reduces electrical interference.

Key functions include:

- Converting DC voltage levels from the boost section to the required voltage level for the battery.

- Providing electrical isolation from input to output to protect low-voltage components and ensure user safety.

- Reducing ground loop issues and noise coupling between circuits.

This section commonly uses transformer-based topologies such as flyback, and forward and may include optocouplers or digital isolators for signal feedback across the isolation barrier. The output capacitor types are much like those used in the rectifier section as they are used to filter and smooth the rectified output of the transformer. It’s critical for safe and reliable operation in high-voltage battery systems, especially in EVs, ESS, and industrial applications.

Featured Products

Capacitors

|

Knowles |

Frontier Electronics |

|

|

|

|

|

|

|

|

Rectifier Diodes and SiC MOSFETs

|

CoolCAD |

Frontier Electronics |

|

Rectifiers: · SR30L15 |

Magnetics

|

Frontier Electronics |

MRC Components |

|

Custom |

Custom |

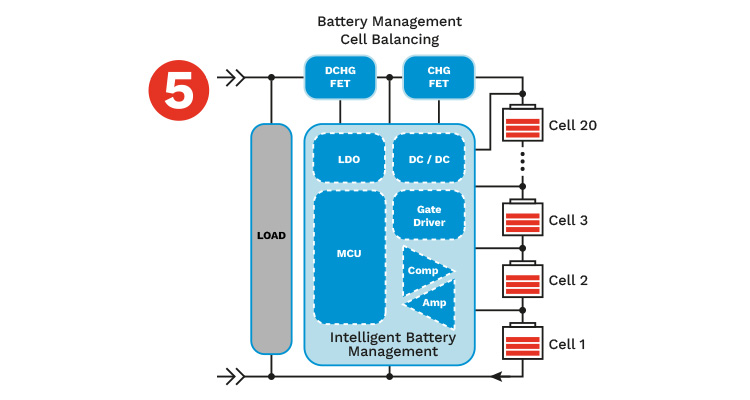

5. Battery Management IC Section

The battery management section includes Intelligent Battery Management ICs. These ICs provide the functions mentioned earlier like cell balancing and load sharing to ensure that all cells in a battery pack maintain equal voltage levels, which is critical for maximizing performance, lifespan, and safety. In addition, these highly integrated devices provide full-cycle battery management, sophisticated battery protection and monitoring, and independent autonomous charge algorithms.

Battery Management IC key functions include:

- Balancing cell voltages to improve capacity utilization across the pack.

- High charge and discharge efficiency

- Preconditioning, fast charge, top-off, and end of charge.

- Over-current, over-voltage, over-temp, and short circuit protection.

- System monitoring with integrated ADC.

There are two types of cell balancing, active and passive. Active balancing uses a dedicated circuit to redistribute the charge of the cells to ensure equal charge by monitoring the individual cell voltages and adjusting the charge/discharge current as needed. Active balancing is faster, more accurate and efficient but requires a more complex circuit.

Passive balancing relies on balancing resistors to bring cells to the same state of charge. Passive balancing is simpler and less expensive, but not as effective and less accurate.

Featured Products

Battery Management Devices

|

Qorvo |

Read our RFMW Expert Product Pick: Qorvo’s PAC22140 and PAC25140 Intelligent Battery Management Solutions

Conclusion

Battery management systems are no longer optional—they are essential for achieving the performance, safety, and reliability demanded by today’s high-power applications. Whether deployed in eMobility, renewable energy storage, industrial equipment, or portable power systems, BMS technology serves as the control hub that ensures precise charging, thermal stability, cell balancing, and fault protection. The five core functional areas of a BMS work together to maximize system efficiency and extend battery life, enabling engineers to meet stringent operational and environmental requirements.

As next-generation designs push the limits of power density, run-time, and environmental resilience, selecting the right BMS solution becomes critical to overall system success. Our portfolio includes robust, field-proven products engineered to meet these challenges head-on.

To learn more about our battery management solutions and discuss which products best fit your application requirements, contact our sales team for detailed specifications and technical support.