|

To produce components such as oscillators and filters, resonant frequency circuits comprised of series and parallel inductance and capacitance are required. At lower frequencies, resonant circuits can be constructed with wire-wound coils and parallel-plate capacitors, but at RF and microwave frequencies, designers take advantage of material properties to create resonant structures without the need for individual components. One such common structure is the microwave cavity, a hollow, closed conductor that confines electromagnetic waves. When a radio frequency source is applied to the cavity at one of its resonant frequencies, standing waves are created and the cavity stores electromagnetic energy. Due to the low resistance of their conductive walls, cavity resonators demonstrate a high Q factor.

Dielectric Resonators

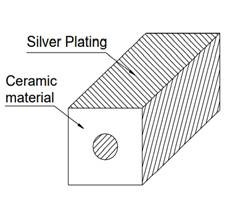

Materials with large dielectric constants surrounded by materials with much lower dielectric constants enable the confinement of electromagnetic waves similar to that of a cavity resonator. Such is a dielectric resonator, the most common being a ceramic disk with high dielectric constant (εr value). The high εr value enables circuit sizes significantly smaller than air-filled cavity resonators.

Dielectric resonators resonate in several modes with the transverse-electric (TE01δ) mode being one of the most commonly used. The resonator can be magnetically coupled to a circuit by several different methods such as coupling the resonator to a microstrip line to create a dielectric-resonator oscillator (DRO).

Coaxial Resonators

Coaxial resonators are constructed by creating a short circuit at one end of a coaxial cable between the centre conductor and the outer shield. The resonant frequency will be λ/4 x the length of the cable. When the 1/4-wave coaxial resonator is part of an oscillator circuit, it has high impedance at the resonant frequency but will look like a low impedance at higher or lower frequencies, acting like a parallel tuned L/C tank circuit.

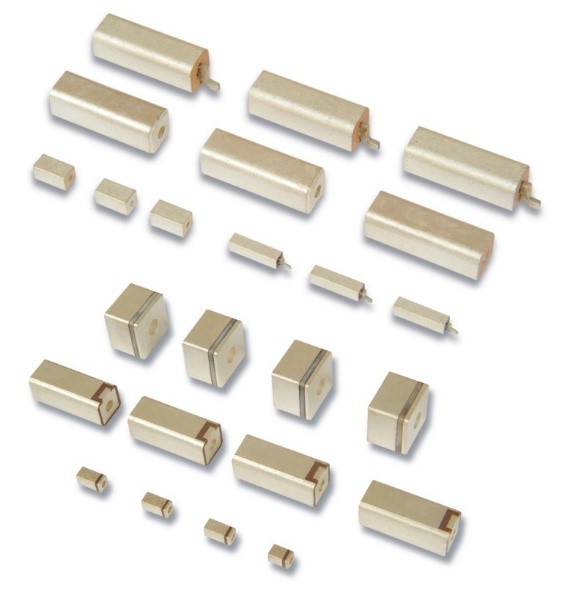

Coaxial resonators can be produced using ceramic materials. A ceramic coaxial resonator will have an outer conductor with an approximately square-shaped cross-section and a cylindrical centre conductor similar to a cable. Due to the high dielectric constant (εr value) of the ceramic insulator, the λ/4 dimension is substantially reduced, and a resonator of very small size is achieved.

Coaxial resonators are commonly used in the design of components like voltage-controlled oscillators (VCOs), coaxial-resonator oscillators (CROs), and filters.

Dielectric & Coaxial Resonator Tuning

For most RF applications, dielectric and coaxial resonators must be tuned to a custom frequency as a step in the manufacturing process. Laser trimming is one possible method of tuning but is rarely utilized due to the high capital equipment cost, making the process viable only for very high volume applications. Customers with lower volume demand (between 100 and 100,000 pieces), rely on manufacturers who hand-tune resonators. This process has become increasingly economically unviable, causing several US based manufacturers to exit the market.

High Performance Resonator Manufacturer

Sangshin Elecom, is a Korea based manufacturer of ceramic components with manufacturing operations in Korea, China and Vietnam. Sangshin focuses on supplying high performance resonators for a range of applications including VCO’s and RF filters with the manufacturing capability to support high volume requirements whilst retaining flexible production processes that allow specialized needs such as resonators for custom VCO’s.

Sangshin produces square and round dielectric and coaxial resonators with sizes ranging from 2 to 12 mm, offering dielectric constants from 10 to 90. With RFMW support, Sangshin can review customer specific resonator requirements for new designs, or, replacement designs prompted by End of Life situations.

About the author: Colin Field has worked in the RF industry since 1984 and has over 30 years of experience in the application of various filter technologies from VHF to millimeter wave. Prior to joining RFMW, Colin spent 15 years at Vectron in various global sales functions, with a focus on timing and filter solutions for military, industrial and communications markets.

|