|

|

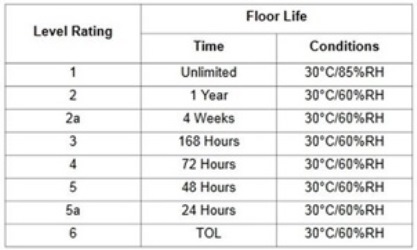

A Moisture Sensitivity Level (MSL) indicates the amount of time in which a moisture-sensitive device can be exposed to ambient assembly room environmental conditions and still be safely reflowed (Figure 1).

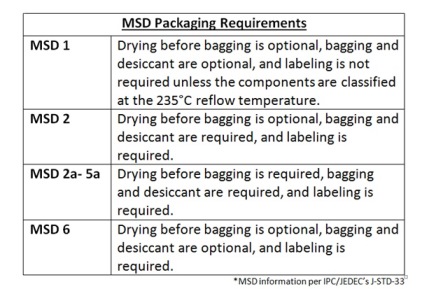

MSL ratings have little to do with the electrical performance of a device, and ratings are not a major consideration by design teams. However, they are a concern for manufacturing personal. The rating only applies to the initial assembly of the design (Figure 2), and in situations where modifications are required to a finished product.

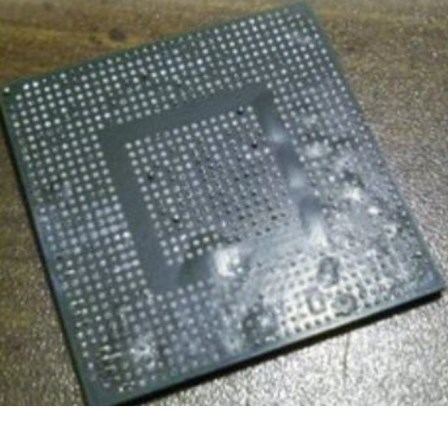

MSLs apply to the plastic packaging of a device because over-molded plastics can trap and retain moisture. If moisture becomes trapped in the plastic, there is a strong possibility that during the solder reflow process, this moisture will rise above the water’s boiling temperature, vaporize, and rapidly expand as steam. The steam created in this event has the capability of pushing out small plastic chips for the molded compound. This phenomenon is commonly known as “popcorning” (Figure 3). The expanding steam in the packaging has the same effect as the expanding steam inside of a corn kernel when intentionally making the snack food known as “popcorn.”

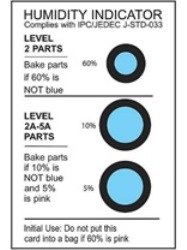

Packaging at a Moisture Sensitivity Level 6 requires a Mandatory Bake before a reflow of the devices can occur. Typically, there are no MSL ratings for air cavity packages. Air cavity packages allow for more ventilation. Any steam present within air cavity packages is properly released through its porous ceramic lid and epoxy seal. If air cavity packages were to be provided with an MSL rating, it would be rated at 1 as air cavity packages allow for an unlimited amount of exposure before the reflow process should occur. In over-molded plastic packaging, retained moisture can be released and the MSL rating time can be reset. Depending on the devices and the shipping packaging, this reset can happen multiple times by dry baking components in an oven at appropriate temperatures and timings. In laymen’s terms, MSL ratings are the amount of allowable time in which a moisture-sensitive device can be left out of a dry pack bag and still be safely reflowed. If the time period expires, it may be reset with a dry bake process. RFMW serves customers that require RF and microwave components and semiconductors, as well as component engineering support. Our highly experienced, technically skilled team can assist with questions regarding product performance that supports design and test engineers. Contact RFMW for additional support or questions Important DefinitionsFloor Life: The allowable amount of time after removal from a moisture barrier bag, dry storage, or dry bake before the solder reflow process. Humidity Indicator Card (HIC) (Figure 4): A cardboard indicator on which a moisture-sensitive chemical is applied such that it will make a significant, perceptible change in color (hue), typically from blue (dry) to pink (wet) when the indicated relative humidity is exceeded.

Desiccant: An absorbent material used to maintain a low relative humidity (less than 10% at 25°C) in moisture barrier bags for dry-packing moisture-sensitive devices. Desiccant may be a silica gel or other absorbent material packed in dustless pouches. Moisture Barrier Bag (MBB): A bag designed to limit the transmission of water vapor and used to pack moisture-sensitive devices. For the plastic packages not to absorb moisture, the moisture barrier bag (dry pack bag) must be handled carefully to prevent punctures. Shelf Life: The maximum amount of time that a dry-packed, moisture-sensitive device can be stored in an unopened Moisture barrier bag (MBB) such that the specified interior bag ambient humidity is not exceeded. The shelf life for dry-packed moisture sensitivity level (MSL) SMD packages is typically a minimum of 12 months from the bag packed date, when stored in a noncondensing atmospheric environment of <40°C/90% RH. Dry Pack: This is the shipping container that consists of desiccant material and a humidity indicator card (HIC) sealed with the components inside a moisture barrier bag (MBB). |

|