|

Using RF Energy for industrial heatingUnlike conventional heat sources used for industrial heating applications, RF energy allows for very controlled material heating using high frequency electromagnetic energy. Typical heating solutions may use infrared radiation or convection heaters to remove moisture. These solutions are effective, but inefficient with regards to the power used and the fact that they dry from the outside of a surface and slowly heat to the inside of the subject material. By contrast, RF energy heats the entire material. An excellent example is the domestic microwave oven used to heat and reheat food in households throughout the world. Many of today’s industrial heating solutions acknowledge this benefit and use a legacy microwave tube, called the magnetron, to generate heat in a material. Limited by the ability to adjust output power or direct energy with changes in material density, the magnetron is a brute force device for material heating. Although more efficient than older technologies, a drawback is that a magnetron’s output power degrades over time, especially in continuously running industrial applications where expensive maintenance and replacement are required. Semiconductor devices are now replacing magnetrons with benefits such as:

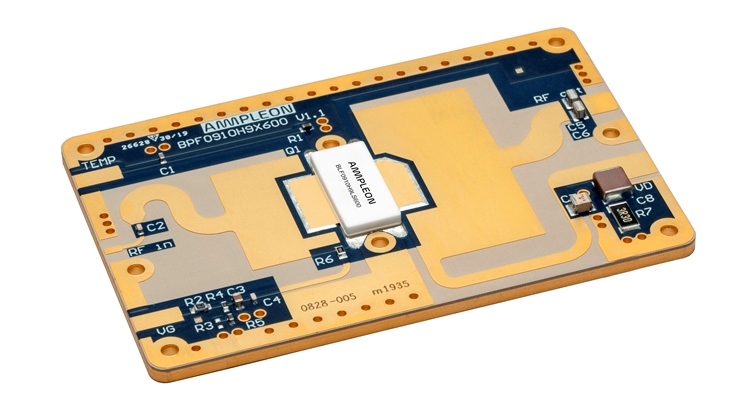

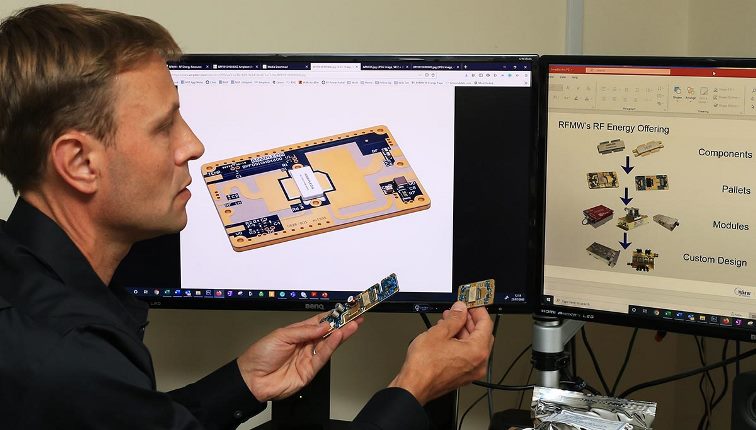

Controllability is really the core advantage of using semiconductor technology, transforming industrial heating products into reliable and smarter solid-state based systems. As a distributor of solid-state RF transistors, RFMW has been supporting customers with a range of diverse RF Energy applications in the 433 MHz, 915 MHz and 2.45GHz bands and has recently added a new, high power, 915 MHz amplifier pallet from Ampleon to their broad selection of devices. The BPF0910H9X600 is a 600 Watt, RF power LDMOS pallet using rugged transistors to ensure best-in class power and efficiency profiles over the entire frequency band while withstanding the harshest mismatch conditions. Pallet amplifiers are easily combined to produce very high power amplifiers that replace older magnetron based designs in current applications such as drying, processing and curing materials or plasma generation.  Tim Daniels, Supplier Business Manager for RF Power products at RFMW, said “As the efficiency of solid-state transistors improves, we are seeing more and more customers with an interest in evaluating solid-state solutions to replace magnetrons. Until now, we have only had pallets for 433MHz and 2.45 GHz RF Energy application. This 600 Watt, 915 MHz pallet from Ampleon fits a vital niche in our RF Energy portfolio.” Expanding on the benefits, Mr. Daniels says “Although we supply the RF power transistors, tested, 50-Ohm matched pallets speed up the design cycle considerably, while taking risk out of the project. Customers can build a prototype in a matter of weeks and focus on their system and process control software. When comparing solid state to a magnetron, you don’t need a high voltage power supply, and the reliability of solid-state is far superior, so you don’t need to replace the PA like you would with a magnetron.” At the heart of the BPF0910H9X600 pallet is an Ampleon ninth generation, 50 Volt LDMOS transistor. The pallet has a typical efficiency of 68% and is optimized to cover the 902 to 928 MHz ISM band. It is suitable for both narrow and wideband 915MHz applications. An embedded copper heat spreader is incorporated into the pallet to improve overall system thermal design, and a built-in temperature sensor allows over-temperature protection. Mr. Daniels goes on to say “We discovered early on that some customers needed more integrated solutions than the traditional, discrete RF power transistor components we offer. Ampleon has tackled this problem by providing fully tested pallets. This helps our customers to build power amplifiers quickly without spending time on the RF power amplifier design or difficulty of soldering a transistor to an embedded copper coin; something that is common for base station customers who produce high volumes but can be costly in small batches as well as difficult to do correctly.” “Every Ampleon pallet is thoroughly tested and includes an X-ray for voids underneath the transistor. While this is an excellent method for high volume production, RF Energy applications are still relatively low volume. The yields can be low until you get the process right, so buying in a ready-to-go pallet removes a lot of complexity and time from the design cycle” says Mr. Daniels. “We can often help customers have their prototype up and running in a matter of weeks.”  RFMW offers complete line-ups based upon a comprehensive portfolio of rugged transistors and pallet modules that ensure best-in class power and efficiency profiles over the entire frequency band while withstanding the harshest mismatch conditions. Solid state solutions enable several improvements for existing RF powered applications while enabling a host of new ones like plasma lighting, medical treatments or automotive ignition systems. Solid state RF systems easily replace magnetrons for diverse applications such as Industrial heating and drying, Chemical processing, Plasma generation, Commercial cooking (restaurants, fast reheat and thawing), Medical treatments and Consumer microwave ovens. For further information and application support on the BPF0910H9X600, or other high power, ISM band applications, please contact RFMW. |

|