One of the most typical applications of microwaves for industrial processing is the physical effect of dielectric heating, which has plenty of practical implementations in food and material processing.

In dielectric heating, an electromagnetic field is applied to a material and collision-related friction generates heat when polar molecules (e.g., water) or ions of that material begin rotating and translating.

Solid-State Technology

Magnetrons claim a consolidated history with heating applications. Still, solid-state technology shows significant advantages where accurate real-time control of radiation parameters brings valuable results in process duration, high-quality manufacturing, and – especially in terms of complex thermal profile engineering – capability. Solid-state technology benefits can commonly be seen in cases with demanding applications like those of the Industrial, Scientific, and Medical (ISM) fields that require highly accurate processing enabled by real-time interaction between radiating devices and processed materials.

Industrial Applications of Microwave Heating

Recent microwave-aided industrial applications include semiconductor device manufacturing, materials curing, mild food processing, synthetic diamond growth, and hydrogen production. Microwaves have also been adopted in various scientific applications such as:

- Nanomaterials development

- Pharmaceutical chemistry

- Particle acceleration

- Space thrusters

- Additive manufacturing with techno polymers

- Environmental decontamination and various material diagnostics

Microwave sources are also used in modern medical treatments such as:

- Hyperthermia

- Tissue ablation

- Dermatological treatments

- Localized drug activation

- Diagnostics and many others

As a counterpart to magnetron-based, almost open-loop microwave generators, innovative modular and scalable solid-state architectures have been developed after careful hardware and software design with RFMW and the LEANFA engineering team.

Phase Shifter Kits

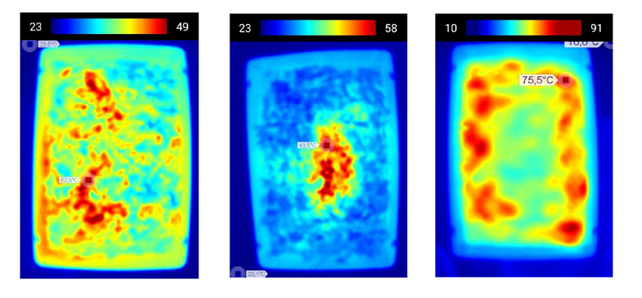

Experience shows that new solid-state RF generator systems’ most significant benefits come from accurate power handling, absolute spectral purity, and the phase shifting capability of several generators in systems that are managed as frequency-synchronized arrays.

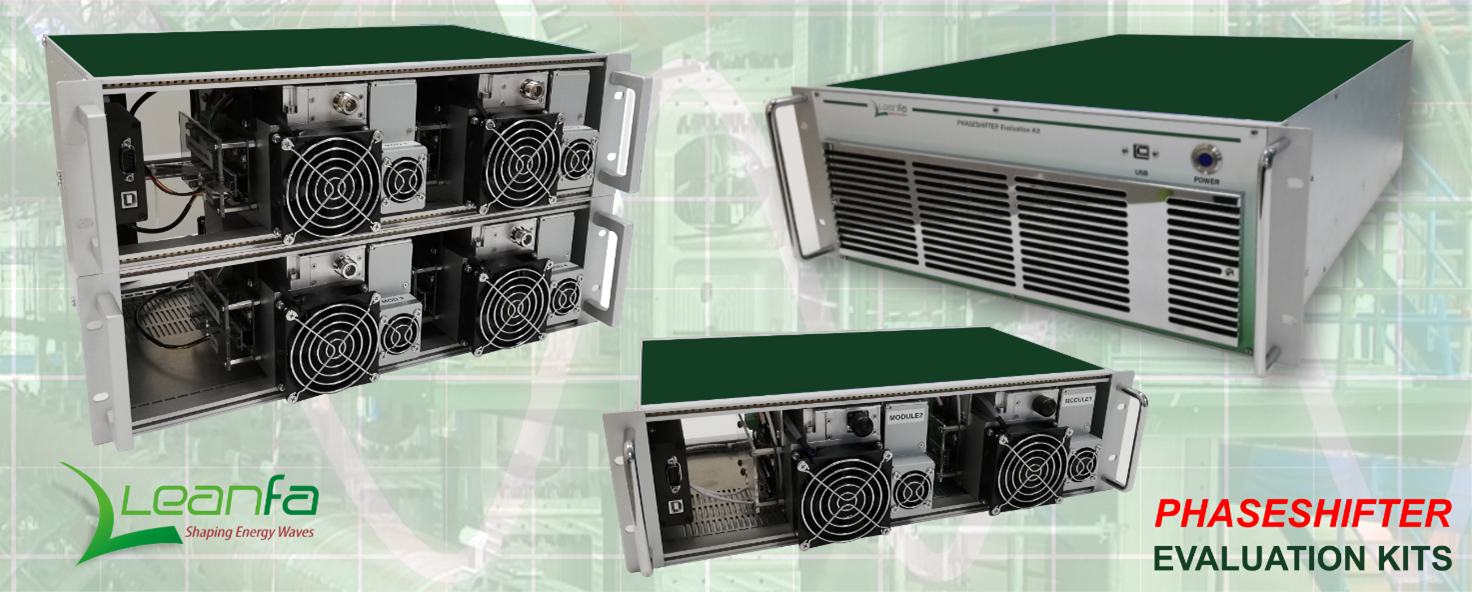

For this reason, RFMW offers LEANFA’s PHASESHIFTER Evaluation Kits. These are true plug-and-play devices managed by a user-friendly Windows application that allows the user to exploit the advanced parametric control of solid-state generators and monitor the parameters of the microwave heating system in real-time.

PHASESHIFTER Evaluation Kits are based on the concept of a multi-feed phased array and provide the possibility to synchronize generators onto the same radiating frequency, which for solid-state generators corresponds to a single spectral line. When the generators are synchronized, a 360° relative phase shift can be applied between each of the microwave feed outputs to adjust the radiation parameters affecting the target material. The aim is to accurately ‘shape’ the desired thermal profile in both the time and space domains.

Control Software

LEANFA’s LeanOn software platform is highly user-friendly. It provides most control and monitoring operations on a single page to allow timely actions by the user to follow the progression of the application process. The PC and PHASESHIFTER kit are connected by USB, providing a bridge to the internal high-speed RS485 bus to operate the generator.

If the sync mode is active, selecting a frequency value also sets the corresponding value for all the kit’s generators automatically. If sync mode is unselected, each frequency value can be set independently within the admitted range. The mentioned advanced functionalities and a useful Recipe Editor are unique tools for R&D laboratories looking to exploit the benefits of solid-state microwave technology.

For further information or to discuss your solid-state microwave application, contact RFMW today!

About Marco Fiore

|

Marco Fiore is a Co-Founder and Business Development Manager at LEANFA. With 23 years of industry experience, Marco holds a degree in Electronics Engineering and supports his organization through lead generation, partnership management, and design consulting. With a passion for solid-state microwave technologies, Marco enjoys the opportunity to learn from new customers and share his industry expertise with others through global workshops, presentations, and lectures. |